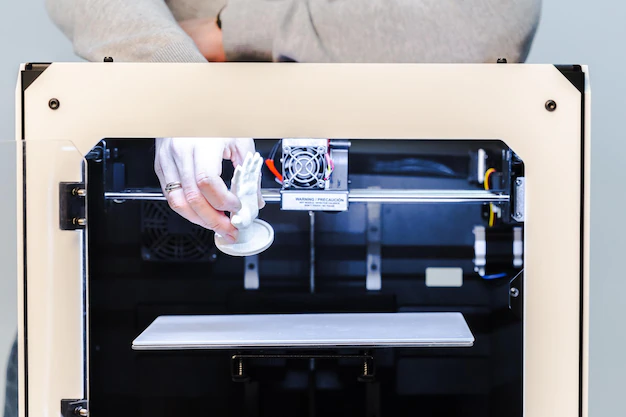

How to remove 3d prints from the bed without any damage- 12 ways

Many professionals always try to find a way to print without their 3d prints sticking on the print bed. This is because removing 3d prints may cause problems to both the print and the bed when not done rightly. That is why this blog has been drafted to provide the necessary skills on how to remove 3d prints from the bed without any damage.

After abiding by all pre-printing procedures like cleaning the print bed, setting time for how long printing will take, etc., and the print still gets stuck on the bed, you will have to take your time to remove it gently or face destroying the print and the bed.

Cool the material down

This is the first protocol you follow right after printing. Leaving the material to cool down not only makes it easy for removal but also, the print becomes durable.

The material is left to cool to room temperature. Once the print material is made from Polylactic acid, the print gently falls off without any external force. This happens because polylactic acid does not require the use of adhesives to help it get stuck on the bed.

This is one of the reasons why polylactic acid is one of the most used materials in 3d printing- It is easy to remove from 3d beds.

Use external force

Will this method not destroy the print or the bed? It may, but there is a way to remove the 3d prints from the bed with force without any damage.

The first thing you have to look out for is a place to hold on to the print to aloe a firm grip. After doing that, you place your other hand on the bed. Gently push or pull the print off the bed.

You may not be able to remove the whole 3d prints from the bed but try to lift just a portion. Once you are done with that, you will successfully remove the print with other methods I will go on to explain.

Scrapping

This is also another dangerous method of removing ed prints from the bed because it can damage both the print and the bed.

Scrapping is mostly done with a spatula with a strong handle. To ensure the safety of your print and bed, make sure you lift a portion or section of the print from the bed. This will allow the spatula to follow the pattern of safe removal and easily remove the print off the bed.

The blade of the spatula used must not be sharp enough to cut through the print or scratch the surface of the bad.

Scrapping must also be done with the blade facing the opposite direction of where you stand to avoid self-injury.

Changing your print bed

In many books or blogs, you will see build plates. Do not worry, it is the same thing and can be used interchangeably. Changing your print bed does not necessarily mean that you should try out any other build plate. It should be changed to a flexible build plate.

The main aim of removing prevent is to prevent damaging the beds and the prints. Since you have a flexible build plate, you need to allow the plate and print to cool. In the first method, you only allow it to cool and the print falls off. But with the use of a flexible build plate, you will have to bend the plate after cooling to facilitate the removal of the print.

Make sure you take correct measurements when you go out to buy flexible build plates. Taking the measurements will allow you to get the right build plate which will fit into the printer without any trouble. See also, how to use a diode laser hair removal machine.

Examples of the best flexible build plates on the market are Pro L, wham bam Flexi build plate, filament fula-flex, etc.

Use 3d printing raft

3d printing raft serves as a mattress for print. It enables the prints to be on a leveled surface. The use of rafts helps in the easy removal of complex and large prints.

Because the print is not in direct contact with the surface of the bed, the print can be removed easily. Once you remove the print, the raft may be attached to the surface of the print and it is removed the same way a banana is peeled. The print can also be removed by first removing the prints off the rafts.

This prevents the prints from getting attached to the surface of the build plate, hence there will be no use of a spatula, alcohol, acetones, or washing soap to clean the bed.

It is suitable for materials printed from Acrylonitrile butadiene styrene.

Flossing

We are not cleansing any teeth today but we are borrowing the services of the dentist to help remove our prints. This is by far means, one of the most dangerous methods to use. The use of a rope preferably, dental floss, or any thin strong wire to help push or pull the print off the bed.

This can easily alter the appearance of the print because it can break easily.

The best way to floss off the print is to wrap the dental floss at the base of the and pull it towards you gently but strong enough to take it off the bed without any damage.

Use of water

This may be the simple method to use but that doesn’t make it the easiest way to remove 3d prints from the bed.

Placing the bed in water or under running water breaks the bond between the adhesives and the print. Once this doesn’t work, you can slightly warm water, pour it at the base of the print, and wait for it to cool before removing it. If you can lift a section, you can use other means like the use of a spatula to remove the print.

Use of solvent

Some adhesives can be very hard to remove with water. This is where the use of solvents dissolves the adhesives and breaks the bond holding the print to the bed together.

The first choice of solvent used is alcohol. If the print is still stuck on the build plate, use acetone. Just pour or spray the acetone at the base to dissolve the adhesive.

Pour a little solvent to allow a gap between the bed and the print to remove the 3d print off the bed by other means such as scrapping.

Pouring too much solvent will destruct the surface of the build plate and affect printing.

Freezing the bed

When sensitive materials like aluminum are used to create a build plate it contracts and expands at certain temperatures. When the temperature is low, aluminum contracts making it very easy to pull off or remove 3d print from the bed.

We can do this by placing the printer bed in a freezer together with the print to contract the build plate. Once it becomes very cold, push or pull the print.

Moreover, you can floss after freezing since the binds have been weakened.

Reheating the bed

As freezing allows the build plate to contract, reheating also expands the build plate.

Due to the expansion of the build plate, it will decrease the strength of the bind holding the print and then it will fall off easily when pushed or pulled.

Good printer settings

This is a method most professionals do not use but can also prevent you from going through the rigorous process to remove 3d prints from the bed.

One of the good settings to allow easy removal of 3d prints is to have some distance between the bed and the printer’s nozzle. The distance between these two will prevent the printing material from spreading too much on the surface of the bed thereby reducing the bond between the print and the build plate.

The closeness of the nozzle to the printing bed can be detected when clunking sounds are heard. This can be corrected by adjusting the z-axis away from the nozzle either automatically or manually.

This will facilitate easy removal of 3d prints from the bed.

Cleaning your 3d printer bed

Cleaning the bed will help remove residues from previous printing work.

This will enable a flat and leveled surface for the print to facilitate easy removal of your object without any damage done to it. Read also- Is 3d printing an expensive hobby?

Conclusion

We have learned that we can use more than 2 ways to remove 3d prints from the bed to get the print in one piece without any damage.

Learning these various methods will provide you endless means of removing your 3d print with ease when it gets stuck.